Wall Basics

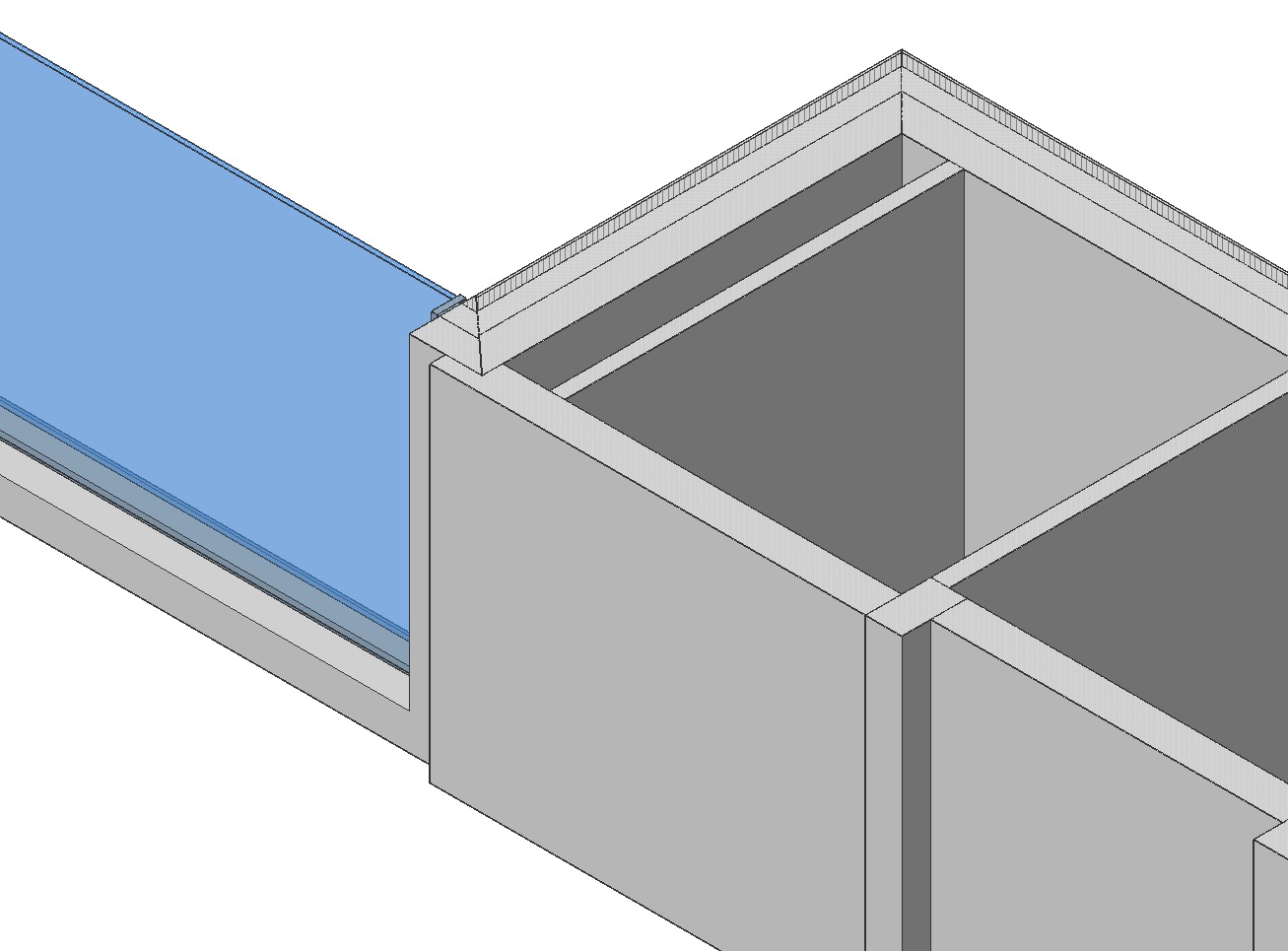

Here a typical Wall Detail I get from Clients.

Stair Case Lift Core docked to the Exterior Walls and slightly inserted.

The typical Exterior Wall (here with flush Window) has 25 cm structural concrete,

while the Stair Case Core has 30 cm concrete.

Beside that difference in concrete thickness both use the same Composition.

Concrete variable 25-30 cm / Insulation 18 cm / Cavity 10 cm / Sheet Metal.

This works well with Composition with variable Concrete Ply thickness.

Left is Inside, Right Exterior.

Problem 1.

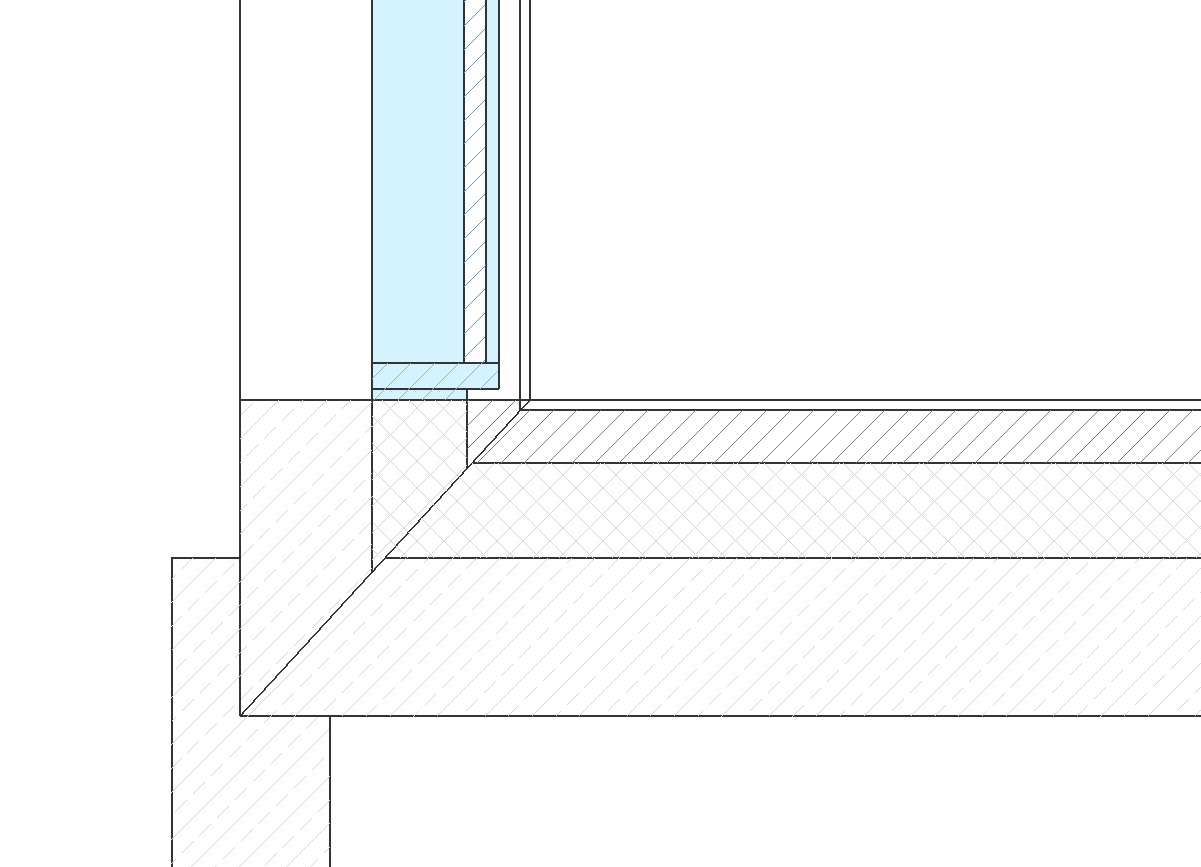

If you look at the Top Plan Section, because of the difference in thickness (of Concrete Ply)

the mitered Wall Join does not look very good in Section.

If I change to a flush Join and start to manually join on a per Ply basis, run BIMSUGGEST,

it will find .... nothing.

(I would have to do that manually for 4-20 times per Story per Building)

Problem 2.

Do I get rid of the Solids Boundaries Lines in final Sections ?

So that there is a single Surface for all touching Structural Concrete Parts etc.

Problem 3.

Inserted Windows.

I often need Windows touching L Wall Joins like in this example or Corner Windows

(without vertical Frames in the Corners).

So I will often come very close to Wall Ends. If I exceed a Wall is easily broken.

Repositioning or even deleting an inserted Window will not heal the Wall again.

Same will happen with design changes, like when Corner Windows will be cancelled.

The Void in Walls will stay.

Comments

-

Certain people can have some wierd design ideas (lets call them architects just for the purpose of discussion

). Thats actually a nice detail compared to many I see. And indeed many times a mitre isn't 45° which can be drawn but how would that be approached from a programming stand point? within a composite, it certainly works on varying polysolids. Maybe some things would need to be approached by using separate elements. It's hard to find the right workflows or techniques for certain situations, in my work I spend 3 or 4 weeks on a project, and a lot of that time is spent just figuring out what information you have and how to deal with it, you develop a whole workflow to automate as much as possible. And then the next project you have to start from zero again because you are presented with a whole host of other challenges.0

). Thats actually a nice detail compared to many I see. And indeed many times a mitre isn't 45° which can be drawn but how would that be approached from a programming stand point? within a composite, it certainly works on varying polysolids. Maybe some things would need to be approached by using separate elements. It's hard to find the right workflows or techniques for certain situations, in my work I spend 3 or 4 weeks on a project, and a lot of that time is spent just figuring out what information you have and how to deal with it, you develop a whole workflow to automate as much as possible. And then the next project you have to start from zero again because you are presented with a whole host of other challenges.0 -

To solve the L-connection problem and apply the same solution to similar connections in the model using BimSuggest do the following:

- Apply a 'parallel' L-connection instead of a mitered (bissector) connection.

- Use BimDrag to apply the desired connection between the different plies

BimDrag recognizes similar parallel L-connections.

In the attached image:top left: 3D model before bimsuggest (clip display of the section plane = Yes)

- bottom left: plan section drawing before bimsuggest

- top right: 3D model aftter bimsuggest

- bottom right plan section drawing after bimsuggest

Connection lines between solids that have the same material are removed because the 'Union Section' property of the materials is set to 'Yes'.

0 -

Thankyou Louis, that is very helpful!

0 -

Thanks all.

Very nice Louis. I learned some other important details.

I have to play with that to understand and get used to.Yes, I also don't understand why the stair cores are always "slightly" off axis.

This or similar happens all the time.

And these connections where up to 4 different Walls meet "nearly" at on point

is something where my current BIM also fails. As you can't T-join something to

an L-Join too near. And if you tinker it in some way you risk that auto join may

flip everything if you touch one of the Walls.

And I see that's where Bricscad BIM by simple Solids shines.

At least from the Solids perspective.As Steve mentioned, that was also the situation where I first thought that it

would be much easier to separate Structural and insulation Finish.

(Like everywhere else not an option because of how Insertions like Windows Work)Currently it may look like both (different) Exterior Walls should L-join.

But in reality the Stair Case has just a closed 30 cm concrete Wall loop.

And other 25 cm concrete Walls touch.

So the Wall similarities are sorted different, just that the Insulation Part, when

these Walls touching the exterior, will give need for a different Composition.

If you would model it this way, by spending some extra Compositions or by

separating Structure from Finish, the situation would look much less strange.As Hans mentioned that there are thoughts about Inserted Objects cutting

everything and more than one Solid in Bricscad,

such live Booleans could also prevent from my broken Walls when Insertion

Objects touch the edges and would heal the Wall automatically.

So just an example to show that such future approaches, maybe complex in

Software, could have large impact and benefits on modeling flexibility.0